EAHV-M-YBL-N air source modular reversible heat pump from the ME-Series family

Modular air source reversible heat pumps with Mitsubishi Electric variable-speed compressor and low-GWP R32 refrigerant, 150 to 180 kW.

R32

This Mitsubishi Electric product uses R32 refrigerant gas, which has a low greenhouse effect.

Quietness up to 83db(A)

The product is designed to minimize noise during air conditioning operations.

Technical sheet

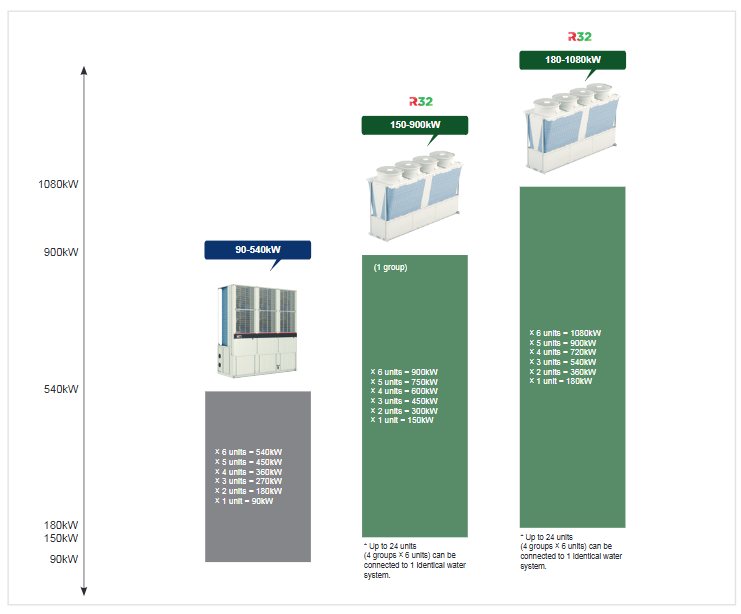

Modular chillers and heat pumps from 150 to 180kW

Power range and footprint

The Mitsubishi Electric-branded air/water modular ranges in R32 EACV and EAHV, thanks to the use of full inverter technology, with proprietary components and control logic, are able to achieve high efficiency and reliability while contributing significantly to system energy savings.

Available in cooling-only or heat pump versions, these units are ideal for both comfort and IT COOLING applications due to their extended operating range.

Two power sizes are available with 150 and 180kW vertical airflow.

The capacity range is further extendable with the ability to connect up to 6 units together in a single group*, and up to 4 groups coordinated by a single master unit.

* each group must consist of units identical to each other.

Thanks to the innovative design that gives the smallest footprint on the floor plan, very high power density, combined with the highest degree of partialization, can be achieved in the smallest possible space.

Modular units: maximum installation flexibility

The capacity delivered by the single unit can range from 150 to 1080kw by combining up to 6 units.

The modular air/water ranges in R32 EACV and EAHV are available in two power sizes with vertical air flow of 150 and 180kW. Thanks to the built-in proprietary control logic and communication protocol, a system consisting of up to 6 units, with a capacity of 1080kW, can be installed in an area of less than 24 m2. The combined control of the units allows the continuity of system operation even when one unit is shut down for maintenance operations.

Outstanding performance and efficiencies that ensure very high levels of energy savings through the use of full inverter technology

The EACV and EAHV units boast full inverter technology on the core components of the refrigeration circuit.

- The four inverter-controlled compressors are automatically adjusted according to the system load;

- optimal control of fan speed through the use of inverters helps to maximize efficiencies and minimize noise.

Full inverter technology, combined with proprietary operating logics, ensure the highest efficiencies and consequent energy savings of the system.

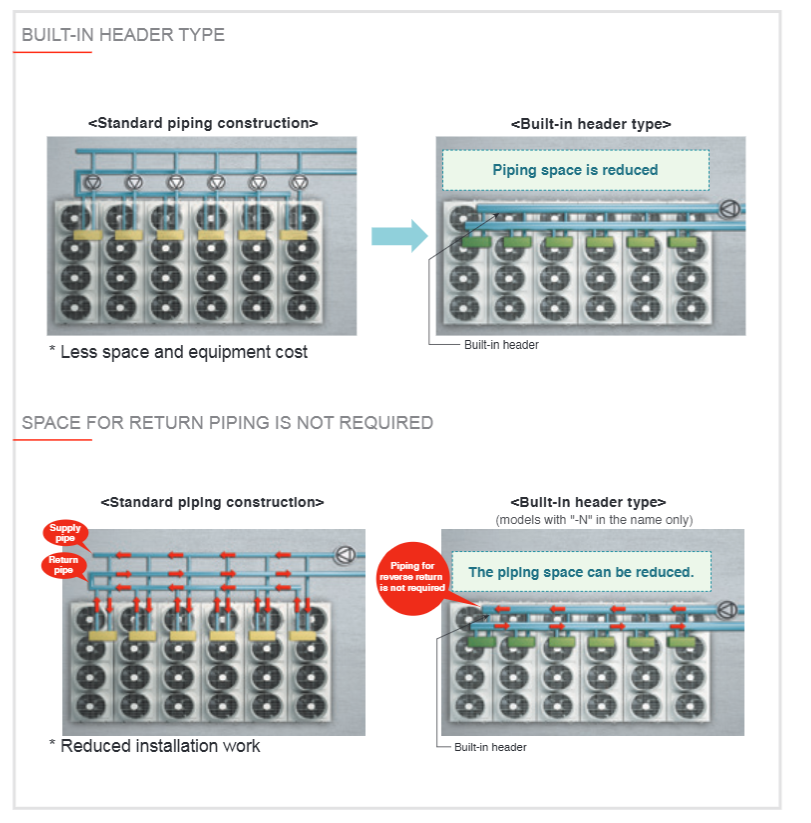

Saving space and installation time

The modular design is designed to reduce the time and cost of installing these units:

- Small footprint helps save space;

- With the integrated hydraulic manifold, the footprint due to hydraulics can be further reduced.

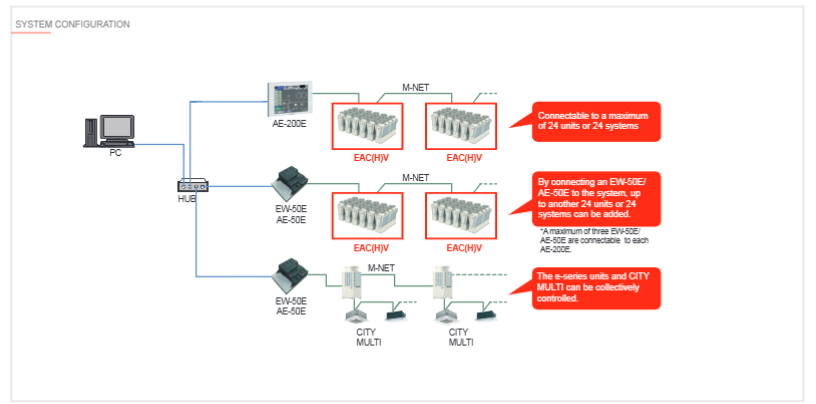

System supervision facilitated

The wide range of options dedicated to user interface and remote connection make these units ideal for inclusion in a centralized system:

- The main operating variables can be conveniently controlled remotely with the controls available in the catalog;

- Through an AE-200E/A supervisor, VRF units and modular units can be controlled simultaneously resulting in a fully Mitsubishi Electric branded refrigeration system.

Technology

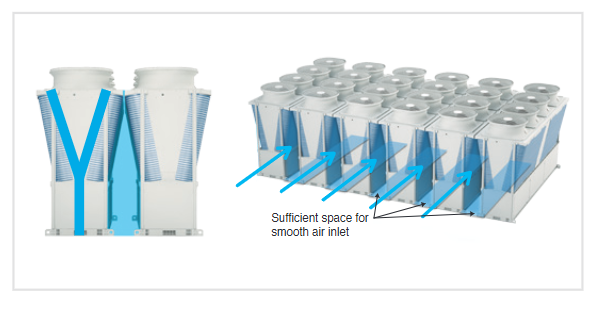

Y-shaped unit design for efficient operation: Guaranteed air circulation

Even when placing several modules adjacent to each other, air circulation on the finned pack heat exchangers remains guaranteed on both short and long sides. This peculiar shape of the unit helps to improve efficiency while minimizing installation space.

Finned pack heat exchangers

The EACV and EAHV units both feature aluminum microchannel exchangers. In particular, the heat pump version boasts an exchanger with proprietary technology that can prevent coil icing even under the most critical environmental conditions.

Mitsubishi Electric Inverter Compressor

The Mitsubishi Electric brand high-efficiency compressor is inverter-controlled and is optimized for the use of R32 refrigerant. The inverter automatically controls compressor frequencies based on various operating parameters, such as outdoor air temperature and load variations in the system, helping to achieve unparalleled seasonal efficiency. Through the use of the liquid injection system there is constant and precise control of the compressor discharge temperature. The induction crankcase heating mechanism is also taken advantage of, which significantly lowers the unit's standby consumption. Each unit is equipped with 4 compressors on independent refrigerant circuits. Together, these technologies ensure unparalleled efficiency and reliability.

The Mitsubishi Electric brand high-efficiency compressor is inverter-controlled and is optimized for the use of R32 refrigerant. The inverter automatically controls compressor frequencies based on various operating parameters, such as outdoor air temperature and load variations in the system, helping to achieve unparalleled seasonal efficiency. Through the use of the liquid injection system there is constant and precise control of the compressor discharge temperature. The induction crankcase heating mechanism is also taken advantage of, which significantly lowers the unit's standby consumption. Each unit is equipped with 4 compressors on independent refrigerant circuits. Together, these technologies ensure unparalleled efficiency and reliability.

Extreme quietness

Sound levels among the lowest on the market, without the need for additional accessories

The design of the fans has been specially studied to minimize their noise emissions (to 83dB(A)) while ensuring maximum efficiency.

Integrated hydraulic manifold

To connect up to 6 units

A version equipped as standard with an integrated hydraulic manifold (-N version) is available.

With optional accessories, available in the catalog, up to a maximum of six units can be easily connected. This eliminates the need to procure connecting piping between units on site, reducing installation work and the floor space of the system.

Simplified single and group control

PAR-W-31MAA or AE-200E

The operating parameters of each unit/group of units can be controlled by matching the remote controller PAR-W-31MAA or through a centralized controller AE-200E.

It is also possible to control the units through external signals provided by a third-party supervisory system. The type of control can be selected according to the customer's need. All basic functions can be performed by the remote controller.

Mitsubishi Electric puts the best professionals at your service to advise you in your choice and guide you through all the steps of purchase and installation.

Find a resellerYour home is unique and deserves a perfect solution. Can we help you find yours?

Let us suggest you